Sustainable Motors: Efficiency Classes and Standards

Explore how motor efficiency classes (IE1–IE5), testing standards, and regulations drive energy savings, lower lifecycle costs, and greener industrial systems

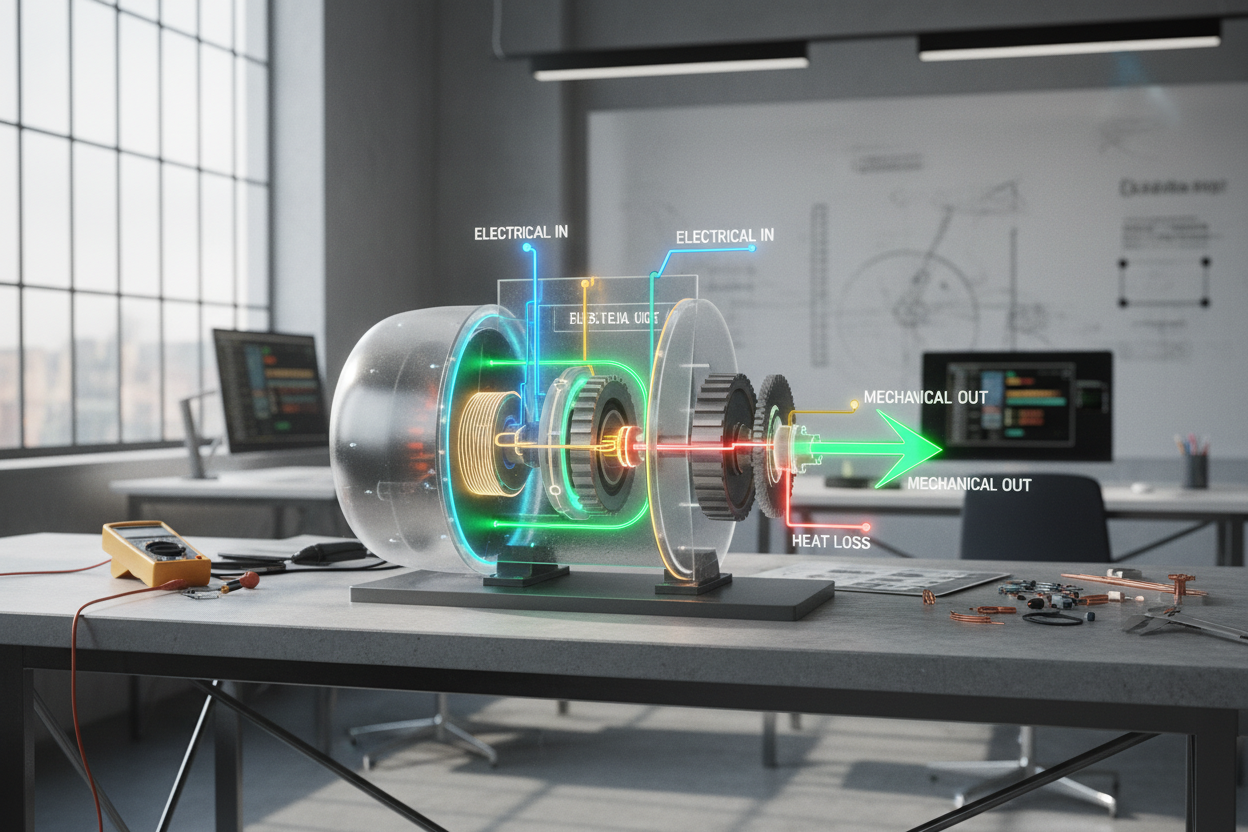

Foundations of Motor Efficiency

Electric motors underpin modern industry and everyday infrastructure, making their performance central to sustainability. At the heart of motor efficiency is the balance between input electrical energy and delivered mechanical power. Losses arise through stator and rotor copper heating, magnetic core hysteresis and eddy currents, mechanical friction and windage, and subtle stray-load losses that appear under real operating conditions. True sustainability begins with correct sizing and understanding the duty cycle, because motors running far from their optimal load waste energy and shorten component life. Power quality, ambient temperature, and power factor also shape outcomes, as voltage imbalance or harmonics can quietly increase heat and reduce reliability. The efficiency noted on a nameplate reflects standardized tests, yet field conditions rarely match laboratory assumptions. A comprehensive view considers alignment, transmission efficiency, and the driven equipment itself. When sustainable motors are paired with efficient couplings, well-chosen gear ratios, and predictive maintenance, they transform energy use from a fixed cost into a strategic lever, improving uptime while lowering total environmental impact.

Understanding Efficiency Classes

Efficiency classes provide a common language for selecting and comparing sustainable motors. Internationally harmonized IE classes rank performance from basic to premium and super premium, guiding buyers toward lower-loss machines across typical power ratings and speeds. These classes are verified under defined test conditions and ensure that two motors claiming similar efficiency truly achieve comparable results. Premium classes reduce losses by combining higher copper fill factors, improved electrical steel, optimized slot and rotor geometry, refined cooling, and diminished fan drag. Advanced topologies such as synchronous reluctance and permanent magnet designs can achieve higher classes at rated load and often retain better part-load efficiency, which matters in variable-torque applications like fans and pumps. Regional labels and minimum efficiency performance requirements complement the IE framework, but their intent is consistent: elevate the baseline and reward better technology. Selecting the right class means weighing acquisition cost against energy savings, runtime, and reliability, then matching efficiency classes to actual load profiles to avoid overspending or underperforming.

Standards and Testing Frameworks

Behind every label is a rigorous ecosystem of standards and test methodologies that create transparency. Standardized procedures specify how to measure input power, shaft output, temperature rise, and power factor, including correction for ambient conditions and instrumentation uncertainty. Methods range from direct input-output measurements to segregated loss approaches that estimate stray-load components with repeatable steps. Certification bodies and laboratories enforce traceability so that published efficiency values can be trusted across borders and suppliers. Documentation practices, nameplate conventions, and tolerance rules protect buyers from optimistic claims and enable apples-to-apples comparisons. Regional minimum energy performance standards drive the market by setting legal baselines, while voluntary schemes incentivize higher tiers through procurement preferences. For users, understanding the framework helps interpret test points versus real-world operation, particularly at partial loads, non-sinusoidal supply, or elevated temperature. Sound testing also underpins retrofit decisions, allowing engineers to quantify expected savings, plan payback, and substantiate life-cycle cost arguments that favor efficient, durable, and well-proven motor designs.

Design Strategies for High Efficiency

High-performing motors are the outcome of integrated electromagnetic, mechanical, and thermal design. Designers minimize losses using thin-gauge, low-loss electrical steel, precision lamination stacking, and optimized slot shapes that balance copper utilization with manageable temperature rise. Rotor innovations reduce resistance without compromising starting capability, while skewing and careful pole design suppress torque ripple and acoustic noise. Airflow and cooling strategies trim fan losses and keep windage in check, complemented by surface treatments that lower friction. For advanced platforms, permanent magnets improve efficiency by eliminating rotor copper losses, and synchronous reluctance machines leverage flux-barrier geometries to deliver high efficiency without magnets. Materials stewardship matters too: insulation systems rated for inverter duty, robust bearings with low-friction seals, and alignment-friendly housings protect performance over time. Thoughtful rewinding can restore efficiency when done to original specifications, but poor practices may increase losses. Ultimately, optimized design ensures high rated efficiency while preserving resilience at partial loads, voltage deviations, and real operating temperatures, where true sustainability is tested daily.

Controls, Systems, and Lifecycle Impacts

The most sustainable motor is part of an efficient system. Variable frequency drives enable speed control that matches process demand, unlocking large savings in pumps and fans through the affinity laws. Replacing throttling or dampers with speed reduction cuts energy and noise while improving process stability. Smart drives add sensorless control, soft starting, and torque limits to protect equipment. Attention to harmonics, EMI, and bearing currents with filters, reactor choices, and grounding brushes preserves reliability. Beyond component efficiency, the system layout matters: low-loss couplings, properly sized belts, straight pipe runs, and well-chosen impellers reduce required torque. Digital condition monitoring tracks vibration, temperature, and energy use, enabling predictive maintenance and continuous optimization. From a life-cycle cost perspective, energy often dominates ownership costs, so premium efficiency frequently pays back through reduced consumption and fewer unplanned outages. When teams evaluate processes holistically, they discover that controls, mechanics, and maintenance practices can elevate a good motor into a truly sustainable solution.

Implementation and Future Directions

Turning ambition into impact starts with structured execution. Inventory existing motors, identify high runtime units, and prioritize replacements where efficiency classes deliver the greatest savings. Specify correct enclosure types, insulation suitable for drives, and bearing protections aligned with power electronics. Commissioning should validate alignment, phase balance, and power quality, while baselining energy sets the stage for verified savings. For sustainability, embrace circularity: repair when economical, choose designs that support disassembly, and plan responsible recycling of copper, steel, and magnets. Procurement can embed eco-design criteria, covering efficiency, durability, low-loss materials, and transparent documentation. Looking ahead, expect tighter minimums, broader adoption of connected drives, and smarter motor-driven systems that coordinate with building and process controls. As renewable generation expands, demand-responsive motors will help stabilize grids without sacrificing productivity. Organizations that combine standards literacy, data-driven operations, and thoughtful end-of-life practices will lead the shift to sustainable motors, capturing energy savings while building resilient, future-ready assets.