Servo vs Stepper Motors: When to Use Each

Compare servo and stepper motors by torque, speed, accuracy, cost, and control. Learn which fits your CNC, robotics, or automation project.

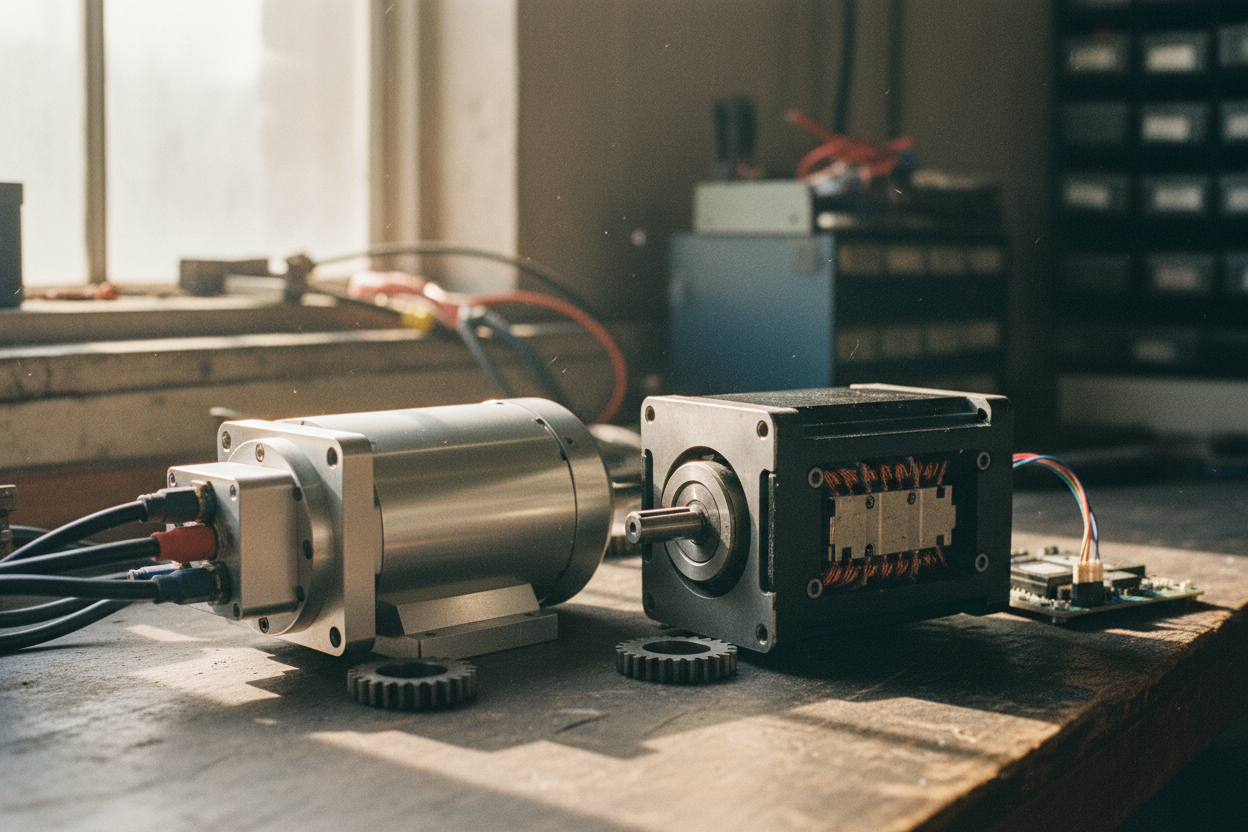

Core Principles — Stepper and servo motors both convert electrical energy into controlled motion, yet they differ fundamentally in how they achieve position, speed, and torque. A stepper motor advances in discrete increments, making it naturally suited to open-loop control where each input pulse corresponds to a step. This simplicity delivers predictable indexing without feedback, and strong holding torque at standstill. A servo motor, by contrast, uses closed-loop feedback—typically via an encoder—so the drive can continuously compare command and actual position, adjusting current to correct error. That enables higher speeds, smoother motion, and consistent torque across a wider range. Steppers are favored for low-cost, simple, and precise incremental moves where loads are modest and speeds moderate. Servos shine when you need high acceleration, dynamic response, and reliable accuracy under varying loads. Understanding these control philosophies is the first step to selecting a motor that matches your motion requirements and system complexity in the broader category of motors.

Performance Characteristics — The torque–speed curve often determines the winner. Steppers deliver strong low-speed torque and excellent holding capability, but torque falls as speed rises, and they can encounter resonance in mid-speed ranges. Microstepping improves smoothness and resolution, though it reduces incremental torque per microstep. Servos typically maintain a relatively flat torque profile up to a base speed and transition into a constant power region, enabling high top speed and strong bandwidth for rapid acceleration and deceleration. Regarding accuracy, steppers offer high step resolution, but missed steps can accumulate if loads spike or friction changes. Servos continuously correct error via the feedback loop, achieving better repeatability under disturbances. Inertia matching is critical for servos; poor matching degrades response and can cause overshoot. With steppers, conservative sizing helps avoid stalls. Consider stiffness, cogging, and downstream backlash too—mechanical elements can limit practical accuracy regardless of motor choice.

Control and Integration — A stepper system usually centers on a current-limited chopper driver and a simple step/direction interface. It's straightforward to integrate, easy to command, and tolerant of budget power supplies. Add microstepping for smoother motion and tune current limits to manage heat and torque. A servo system adds sophistication: servo drives support position, velocity, or torque modes; accept analog, pulse, or fieldbus commands; and rely on encoder feedback—incremental or absolute—for precise control. Proper tuning of PID and feedforward terms is essential to achieve fast settling with minimal overshoot. Wiring may involve shielded encoder cables, grounding for EMI control, and careful routing to prevent noise coupling. You'll also manage faults like overcurrent, overspeed, and following error. Homing strategies, soft limits, and safety interlocks matter for both technologies, but the servo stack demands more diligence in commissioning to unlock its full dynamic performance.

Cost, Efficiency, and Reliability — Steppers are appealing for their low initial cost, simplicity, and absence of feedback devices. However, they often run constant current, generating heat even at standstill, so thermal management and duty cycle planning are important. Their audible noise and vibration can be higher, though microstepping and mechanical damping help. Servos cost more upfront—drive plus encoder—but can be more energy-efficient at speed because they deliver only the current needed, and their closed-loop control reduces waste. Brushless servos have minimal maintenance; brushed variants may require periodic brush replacement. If the axis must hold position without drift under load, steppers excel at holding torque, while servos may add a holding brake or maintain current. Consider ambient temperature, enclosure space, and airflow. Over the lifecycle, the servo's efficiency, speed capacity, and throughput can offset initial cost, whereas the stepper's simplicity minimizes integration risk and spare-part complexity.

Application Fit — Choose a stepper motor for indexing, short move-and-hold tasks, compact CNC axes, 3D printers, valve actuators, and light pick-and-place where loads are predictable and speeds moderate. The strong detent and holding torque reduce the need for brakes, and open-loop control cuts complexity. Add home and limit switches to avoid cumulative error, and consider closed-loop steppers if missed steps are unacceptable. Opt for a servo motor when you need high speed, rapid acceleration, variable or unknown loads, or long travel with tight cycle times—think robotics, packaging, conveyors, gimbals, and precision automation. Servos absorb load variations, maintain torque at higher rpm, and provide smoother motion profiles. If the process penalizes lost motion—scrap parts, safety concerns, or downtime—servo feedback can be invaluable. In hybrid scenarios, a machine may use steppers on auxiliary axes and servos on primary axes to balance cost and performance.

Selection Checklist and Practical Tips — Start with a clear motion profile: travel distance, move time, dwell, and required throughput. Estimate load torque, friction, and inertia, include couplings and gear ratios, and calculate RMS torque and peak demand. Steppers fit when you need affordable precision at low-to-medium speed, strong holding, and straightforward control. Servos fit when you need dynamic response, high bandwidth, and reliable accuracy under changing loads. Ensure power supply headroom for acceleration, and verify driver or drive current limits. For steppers, mitigate resonance with microstepping, dampers, or jerk-limited profiles. For servos, aim for good inertia matching, validate tuning, and set follow error thresholds. Add home routines, soft limits, and mechanical stops as safeguards. Plan for thermal performance, EMI practices, and cable management. A disciplined sizing and validation process will reveal whether a servo or stepper best aligns with your motor control goals.