Inside a Brushless Motor: Components and Benefits Explained

Explore a brushless motor's stator, rotor, magnets, windings, sensors, and ESC, and how electronic commutation boosts efficiency, torque, and lifespan.

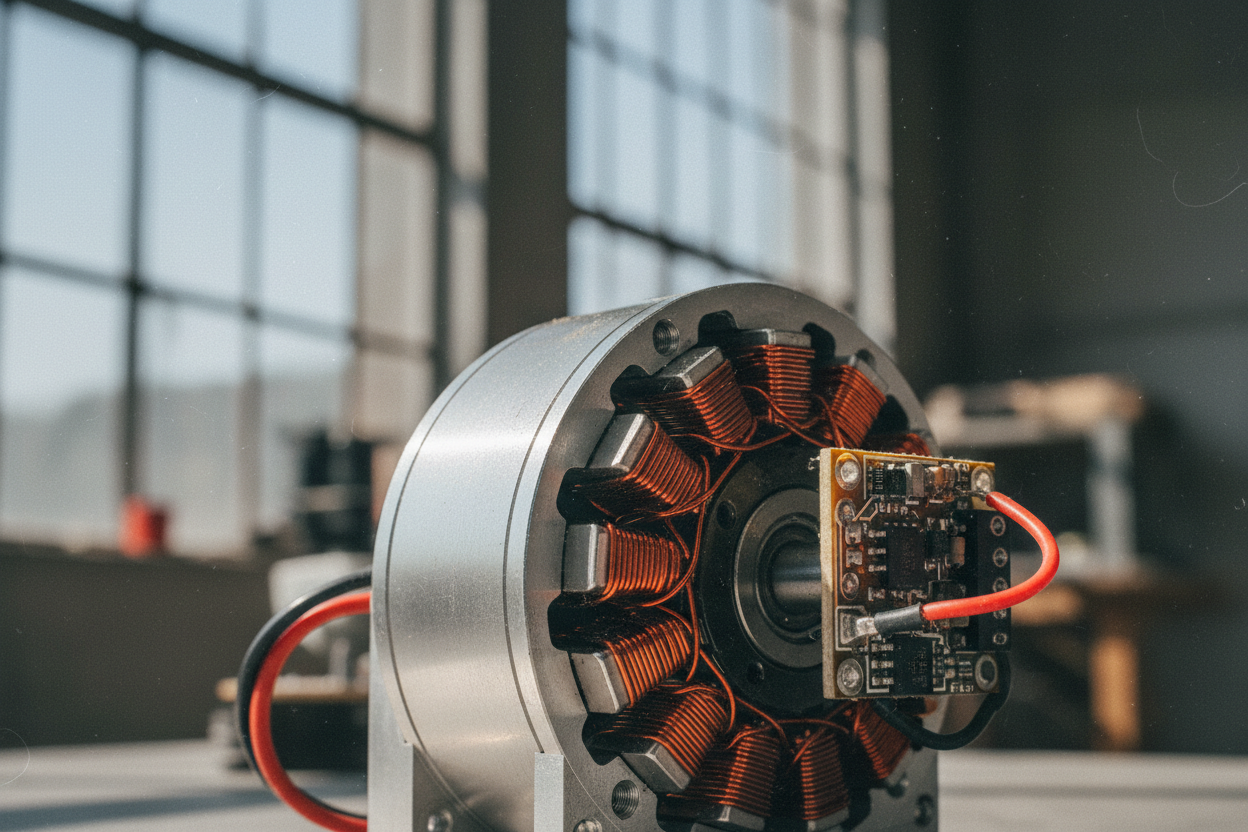

Core Architecture. A brushless motor is a type of electric machine where the stator holds energized windings and the rotor carries permanent magnets. Instead of sliding brushes and a commutator, it relies on electronic commutation to switch current through the phases, creating a rotating magnetic field that pulls the rotor smoothly along. This design removes frictional contacts, slashes electrical arcing, and dramatically reduces wear, making brushless motors a durable choice across many motors applications. A typical unit includes a laminated steel stator core, precision bearings, a balanced shaft, and a tightly controlled air gap. Three-phase excitation is common because it produces consistent torque and manageable control. Torque is generated as magnetic fields in the stator align with fields in the rotor, with timing governed by sensors or sensorless algorithms. The result is accurate speed control, high torque density, and clean response to load changes. Compared to brushed designs, the brushless approach achieves higher efficiency, better reliability, and quieter operation, all while supporting advanced control features such as regenerative braking and field weakening for extended speed range.

Stator and Windings. At the heart of the brushless motor's stationary side, the stator uses thin laminations of electrical steel to reduce eddy current losses and improve efficiency. Slots in the stator hold windings that can be distributed across multiple teeth for smoother torque or concentrated for compact, high-torque designs. Copper fill factor, wire gauge, and insulation class determine current capability and thermal resilience, while vacuum impregnation and varnish enhance rigidity and heat transfer. Engineers choose star or delta phase connections to match voltage, current, and control goals, and may skew stator slots to lower cogging torque. The heat generated in the windings must travel through the stator core to the frame, so thermal paths, potting compounds, and conductive housings are crucial. The number of poles and slots shapes back electromotive force and torque ripple, influencing both acoustic character and smoothness. Proper stator design balances electromagnetic performance, manufacturability, and cooling, ensuring the motor delivers repeatable torque over its intended operating range without excessive temperature rise or acoustic noise.

Rotor and Mechanics. The rotating assembly centers on a rotor equipped with permanent magnets, supported by low-friction bearings and a straight, well-balanced shaft. Two common magnet arrangements are surface-mounted magnets for fast dynamic response and interior permanent magnet layouts that enable reluctance torque and stronger field weakening at high speeds. A robust sleeve or band can contain centrifugal forces on the magnets, preserving clearances in the air gap and protecting against demagnetizing events. The rotor back iron completes the magnetic circuit, while careful magnet segmentation and shaping help tame cogging torque and ripple. Mechanical balance is vital; imbalance generates vibration, accelerates bearing wear, and injects unwanted acoustics. Bearing selection considers load, speed, lubrication, and sealing to withstand environmental conditions. Small design choices, such as shaft shoulder geometry and end cap tolerances, influence alignment and lifetime. By harmonizing magnet grade, geometry, and mechanical robustness, the rotor transforms electromagnetic intent into reliable torque output, preserving efficiency and smoothness across a wide speed range.

Commutation Intelligence. A brushless motor depends on a controller to orchestrate electronic commutation, usually via pulse-width modulation and phase timing informed by Hall sensors, an encoder, or sensorless back EMF detection. Trapezoidal commutation is straightforward and efficient, while sinusoidal methods reduce torque ripple and acoustic noise. Advanced field-oriented control resolves stator currents into torque-producing and flux components, yielding excellent low-speed control, high efficiency, and rapid dynamic response. Controllers monitor current, voltage, and temperature, applying protections against overcurrent, undervoltage, and thermal overload. Features such as regenerative braking, soft start, and field weakening extend capability across operating conditions. Careful tuning of current loops and speed loops, filtering for EMI, and proper dead-time management prevent losses and instability. Matching the controller to the motor's electrical constants, phase resistance, and inductance ensures clean commutation. Done well, the control stack turns the motor into a precise actuator, delivering predictable torque, accurate speed, and dependable operation under changing loads.

Performance Benefits. The brushless topology brings compelling advantages: higher efficiency from reduced electrical and mechanical losses, lower maintenance thanks to the elimination of brushes, and outstanding reliability under continuous duty. With excellent power density and refined torque control, these motors often run cooler for the same output, translating into longer component life and better energy use. Torque ripple is minimized with proper design and commutation, improving smoothness and reducing acoustic signature. Wide speed ranges are achievable through field weakening and careful control, while regenerative capability can recapture energy in decelerating systems. Precision control enables tight speed regulation, fast acceleration, and consistent performance in automation, mobility, and HVAC. Safety also benefits from predictable thermal behavior and robust protections in modern controllers. While results depend on sizing, cooling, and tuning, well-executed brushless systems reliably outperform many brushed counterparts in longevity, responsiveness, and overall operating cost, making them a strategic choice for demanding motors applications.

Selection Tips. Choosing a brushless motor begins with the torque-speed profile and duty cycle. Translate load requirements into continuous and peak torque, then match voltage, current, and kV or Kt to the controller and power source. Consider cooling methods, ambient temperature, and airflow, since thermal headroom governs reliability. Evaluate gear ratios or direct drive based on stiffness, backlash, and efficiency. Check phase resistance, inductance, and pole count to anticipate current ripple and control dynamics. Mechanical fit matters: shaft diameter, keying, mounting patterns, and allowable misalignment influence installation quality. Confirm EMI measures, cable shielding, and connector quality to maintain signal integrity for sensors. Look for appropriate IP ratings where dust or moisture is present. During commissioning, tune current and speed loops, verify commutation alignment, and log temperatures under worst case load. Maintenance is modest but essential: monitor bearings, keep the motor clean, and ensure secure fasteners. With deliberate selection and setup, a brushless motor will deliver efficient, quiet, and durable service.