Decoding Motor Efficiency Ratings: What They Really Mean

Decode IE and NEMA Premium motor labels: what efficiency ratings mean, how they're tested, and how to use nameplate data to cut energy costs and speed ROI.

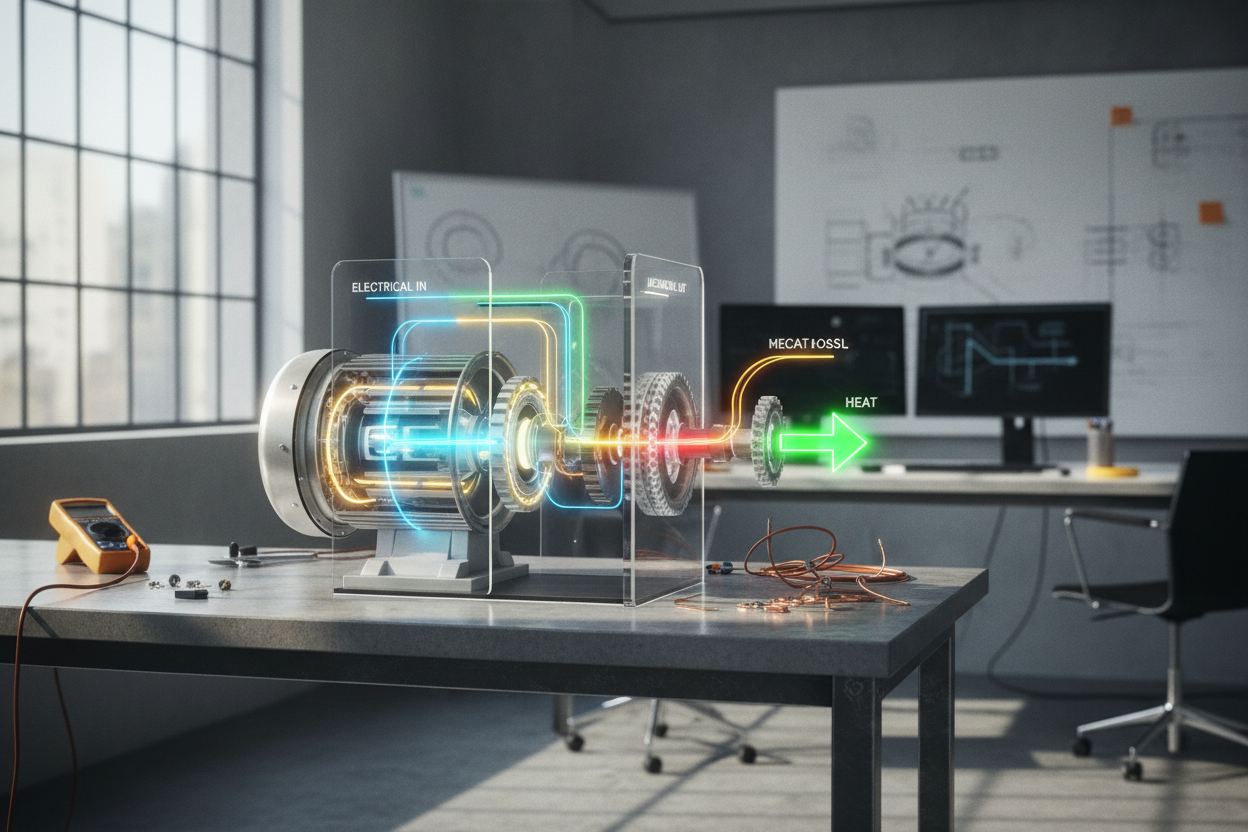

Efficiency Fundamentals: Motor efficiency is the ratio of useful output power at the shaft to the input power drawn from the source. In simple terms, efficiency equals output divided by input, and it reflects how well a motor turns electrical energy into mechanical work. Losses eat into this conversion: stator and rotor copper losses, core losses from magnetic hysteresis and eddy currents, friction and windage, and stray-load losses that vary with operating conditions. High efficiency means less energy wasted as heat, smoother operation, and longer component life. Do not confuse efficiency with power factor; efficiency measures energy conversion, while power factor describes how effectively current contributes to real power. Motor nameplates typically list rated power, voltage, current, speed, power factor, and a nominal efficiency value tested under defined conditions. Real performance depends on installation details, duty cycle, and how closely the motor operates near its rated load. Understanding these basics enables smarter selection, sizing, and control strategies that cut energy usage without sacrificing reliability.

How Ratings Are Established: Efficiency ratings come from standardized test methods that compare input watts to shaft watts under controlled conditions. Nameplates often show nominal efficiency, a representative value derived from testing multiple units. Real motors exhibit manufacturing variation, so standards allow a tolerance range; a given machine's actual efficiency can be slightly higher or lower. Ratings are typically stated at full-load because it provides a consistent comparison point, but motors have efficiency curves that vary across the load range. Many markets use efficiency classes to group products by performance level, and you may see labels indicating an engineered tier above basic requirements. A crucial nuance is that test methods assume specified voltage, frequency, and temperature. Deviation in these conditions changes both losses and speed (through slip), which shifts the rating in practice. When reading a label, consider companion data such as speed, power factor, and service factor, since they influence how the motor will behave in your application beyond a single percentage.

From Label to Reality: What an efficiency rating really means depends on your load profile. Motors rarely run at a single, steady point; they cycle through start-ups, part-load, and occasional peaks. Efficiency typically peaks near rated load, then tapers at lighter loads. If your process runs at 40–60% load most of the time, the relevant number is not the full-load rating but the part-load efficiency along the curve. Ambient conditions matter: higher temperature, altitude, or restricted cooling increase losses and reduce margin. Voltage imbalance across phases can dramatically raise heating, cutting both efficiency and insulation life. Harmonics from non-linear loads and drives add extra copper and core losses. The service factor offers short-term capability but should not be treated as a continuous rating if efficiency and longevity are priorities. Matching duty cycle, torque profile (constant vs variable), and control method to the motor's design ensures the nameplate value translates to predictable, efficient field performance.

Energy, Cost, and Payback: An efficiency upgrade is justified by energy saved, not just the label. The core calculation compares input power at the required shaft load for the old and new motors, multiplied by operating hours to get kilowatt-hours saved. Those savings convert directly to cost reduction and indirectly to reliability benefits, because loss reduction means less heat, lower winding temperature, and slower insulation aging. Consider total cost of ownership: purchase price, installation, drives and controls, energy, maintenance, and downtime risk. Small percentage gains accumulate, especially in continuous-duty services. To estimate payback, use measured kW, load factor, and hours; then quantify maintenance value from lower temperatures and smoother operation. Beware rebound effects: replacing the motor alone may not deliver full savings if mechanical losses, misalignment, or poor power quality persist. Factor in interactions with variable frequency drives, including potential bearing currents, and plan appropriate mitigation so the efficiency promise becomes a dependable financial outcome.

Sizing and System Effects: The most common efficiency penalty is oversizing. An oversized motor runs at low load, where part-load efficiency and power factor are poorer, while fixed losses dominate. Right-sizing aligns the efficiency peak with the typical operating point. Look beyond the motor to the system curve. For pumps and fans, the affinity laws show that small reductions in speed can yield large drops in power, making speed control far more efficient than throttling or dampers. In conveyors and mixers, mechanical design—alignment, couplings, gearing, and lubrication—can outweigh incremental motor efficiency. Maintain good power quality with minimal voltage imbalance and reasonable harmonic levels to keep thermal stress and losses in check. Consider enclosure type and cooling path; a motor that breathes freely runs cooler and more efficiently. Finally, ensure the selected duty rating matches the task, preventing frequent starts or overload conditions that push operation into inefficient, high-loss regions.

Practical Steps to Improve Outcomes: Start with an audit. Measure voltage, current, power, power factor, and harmonics over representative cycles using data loggers. Map the load duration curve and compare it to manufacturer efficiency curves to identify mismatches. If speed varies or throttling is common, evaluate a variable frequency drive (VFD) for precise speed control and demand-based operation. Where the load is steady and near rated, a high-class premium-efficiency motor alone may be adequate. Implement maintenance basics—alignment, clean cooling paths, correct lubrication, and balanced power—to sustain efficiency over time. Update procurement specifications to require a minimum efficiency class, verified testing, and compatibility with drives, including bearing protection where needed. Use condition monitoring for temperature and vibration to catch rising losses early. Finally, track results: validate savings against baseline, refine setpoints, and keep documentation current so each replacement or retrofit builds on proven, measurable efficiency gains.