Cooling Methods for High-Performance Motors

Explore air, liquid, and advanced cooling techniques that boost power density, improve reliability, and extend the lifespan of high-performance motors.

Why Thermal Management Matters. In high-performance motors, thermal limits define usable torque, speed, and lifetime. Copper and iron losses, mechanical friction, and switching ripple generate concentrated heat that elevates winding temperature and creates hot spots in the stator and rotor. Without effective heat dissipation, resistance rises, efficiency falls, lubricant viscosity shifts, and magnets risk partial demagnetization. Elevated temperatures accelerate insulation aging, shorten bearing grease life, and can force derating just when peak output is needed. Robust thermal management spreads and removes heat while minimizing added mass and drag. Designers think in terms of heat flux paths, thermal resistances, and stable temperature gradients from the windings to ambient. The goal is a predictable thermal response across diverse duty cycles, from short bursts to continuous operation. Selecting a cooling method requires balancing power density, environment, maintenance, acoustic targets, and cost. The following methods—air, liquid jackets, direct oil, and hybrid solutions—cover the practical spectrum for modern electric machines.

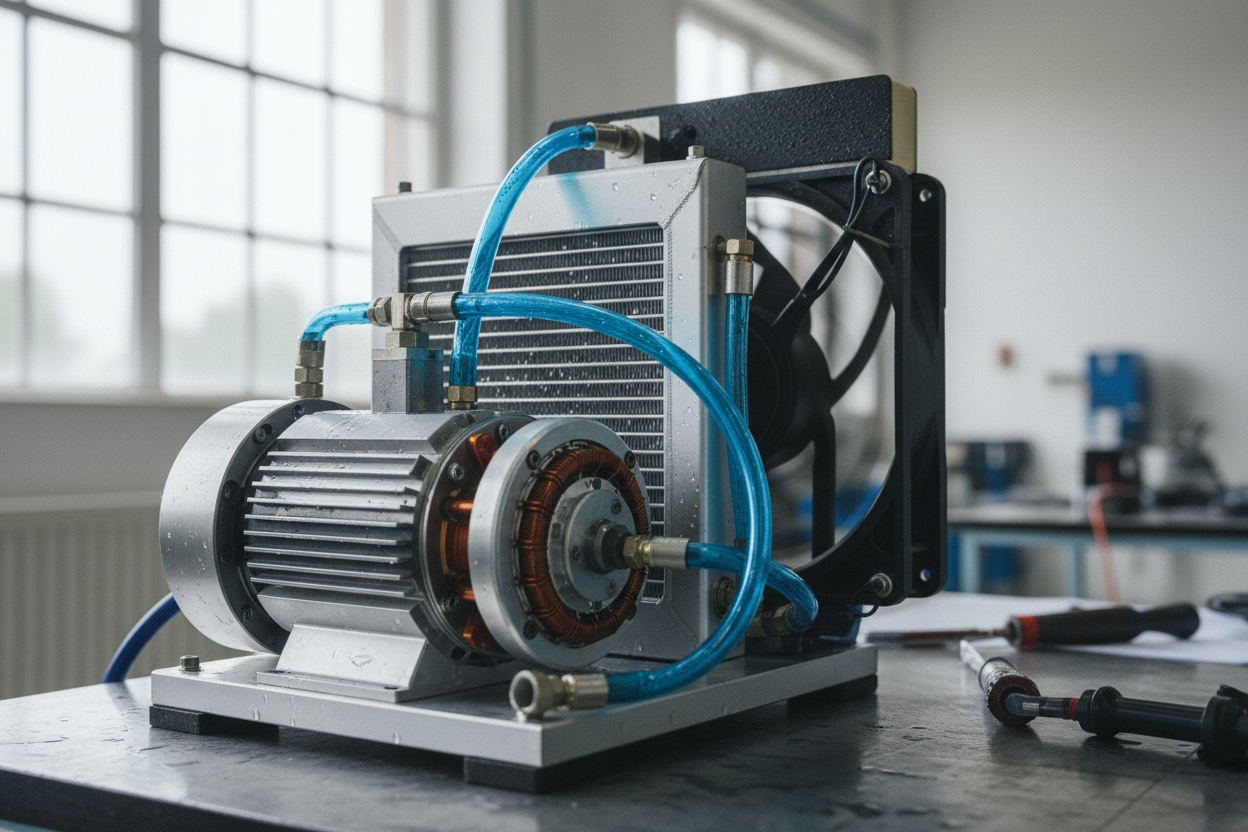

Forced-Air and Fin Cooling. Forced-air remains the simplest, most serviceable option for many motors. External fins increase surface area, while integrated fans or ducted blowers drive convection across hot surfaces. Effective designs guide airflow over the stator housing and end bells, avoiding recirculation and dead zones. Fin geometry matters: taller fins raise area but can stall flow; thinner fins improve boundary-layer disruption but increase clogging risk. Shrouds, flow straighteners, and baffles help convert fan pressure into uniform velocity along critical surfaces. Engineers match fan curves to system pressure drop, considering filters, grilles, and bends. Materials with high thermal conductivity, precise contact to the frame, and smooth heat paths from windings to the shell reduce internal bottlenecks. Advantages include low cost, easy maintenance, and no fluids to manage. Limits appear at higher heat flux, in dusty or hot environments, and where acoustic noise is restricted. Still, with good CFD, smart ducting, and optimized fins, air cooling can carry impressive continuous loads.

Liquid Jacket Cooling. Liquid cooling through a jacket surrounding the stator offers a major step in heat removal. Water-glycol loops or dielectric coolants pass through machined or cast channels that encircle the active core, extracting heat at a high rate while keeping the motor sealed. Helical, serpentine, or parallel microchannels trade manufacturing complexity for pressure drop and temperature uniformity. A complete loop includes pump, heat exchanger, reservoir, and sensors to manage flow and inlet temperature. Key details matter: material compatibility, corrosion inhibitors, galvanic isolation, and reliable seals around end caps and feedthroughs. Thermal interface quality between the stator stack, housing, and jacket is critical; thin gaps are filled with TIMs or impregnation resins to minimize contact resistance. Correctly sized flow keeps the jacket turbulent without undue pumping power. With liquid jackets, motors achieve higher power density and tighter temperature control, enabling compact designs for traction, robotics, and spindles, as long as the system is monitored and maintained.

Direct Oil and Spray Cooling. For maximum power density, many designs route oil directly to the stator end turns or even through channels near the slots, sweeping heat from the copper where it forms. Targeted jets cool the hottest features and reduce thermal gradients that stress insulation. In some architectures, oil is guided through the rotor shaft or distributed by a splash ring to cool magnets and remove bearing heat simultaneously. The oil also lubricates gears and bearings in integrated drivetrains, consolidating systems. Choosing the right fluid is pivotal: dielectric oils protect windings and electronics; transmission fluids can work in shared sumps when electrical insulation is assured. Nozzle placement, droplet size, and flow rate balance cooling with churning losses and aeration. Effective scavenging, filtration, and degassing keep the circuit clean and stable. Benefits include excellent transient control and compact packaging, with trade-offs in seals, complexity, and sensitivity to contamination.

Hybrid and Advanced Solutions. When targets push beyond conventional methods, hybrid strategies emerge. Heat pipes and vapor chambers relocate heat from tight spaces to jacketed frames, using two-phase transport to flatten temperature spikes. Phase change materials can buffer short bursts, while microchannel inserts or additively manufactured housings knit intricate coolant paths directly into the motor body. High-conductivity potting compounds spread heat from end turns to cooled surfaces, and carefully chosen thermal interface materials maintain consistent contact under vibration. Sensors such as thermistors, RTDs, or embedded fiber optics feed control algorithms that modulate flow, fan speed, and torque limits to prevent hot spots. System integration matters: routing quick-disconnects for service, isolating coolants, validating pressure relief, and planning for cold-start viscosity. The most durable solutions combine robust materials, precise manufacturing, and real-time control to sustain performance across varied duty cycles, delivering reliable, efficient, and quiet operation under demanding conditions.