AC vs DC Motors: Which Suits Your Needs?

Compare AC and DC motors on cost, control, efficiency, maintenance, and torque to choose the right drive for fans, conveyors, robotics, or EVs.

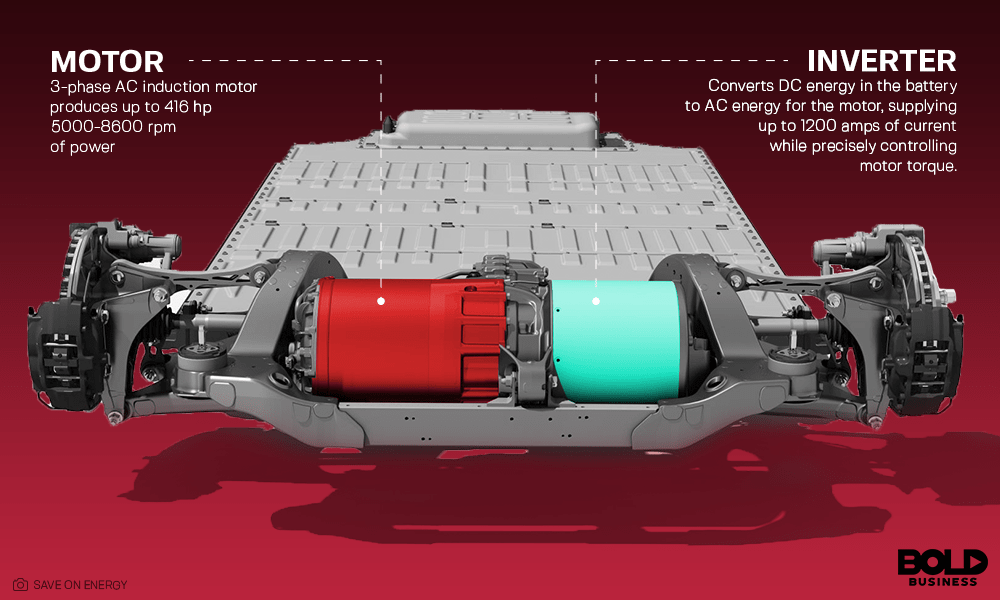

Foundations of AC and DC Motion. At the heart of every electromechanical system are AC motors and DC motors, each converting electrical energy into rotation through distinct principles. An AC motor is powered by alternating current, creating a rotating magnetic field in the stator that induces current in the rotor. In an induction motor, this interaction produces torque with a characteristic slip between field and rotor speed, while a synchronous motor locks to the supply frequency for highly stable speed. A DC motor runs on direct current and relies on commutation to switch current in the windings; this can be mechanical with brushes or electronic in a brushless DC motor. DC designs exhibit torque roughly proportional to current and speed influenced by voltage and back EMF, making them inherently responsive. These foundational differences influence everything from speed control and efficiency to maintenance routines, making the AC versus DC decision central to aligning motor behavior with real-world demands.

Performance, Torque, and Control. Performance needs often dictate which technology shines. DC motors excel at high starting torque and smooth low-speed control, especially with PWM control, enabling precise acceleration, deceleration, and positioning. Brushless DC motors add low electrical noise, high efficiency, and extended life by eliminating friction from brushes. AC induction motors deliver robust, dependable torque over a wide range and, when paired with a Variable Frequency Drive or VFD, offer refined speed regulation, soft-start capability, and energy savings under variable loads. Synchronous AC motors provide exceptional speed stability when exact frequency tracking matters. Efficiency varies with load, temperature, and control method; AC induction designs are strong near rated load, while BLDC systems maintain top efficiency across a broader band. Consider thermal management, duty cycle, and vibration, since heat and mechanical imbalance erode performance. Matching the torque-speed curve to your application ensures smooth operation, minimal losses, and consistent results.

Common Applications and Environments. Real-world use cases reveal clear patterns. AC induction motors dominate fans, pumps, compressors, and conveyors, where constant or predictable speed and long, unattended operation are common. They pair well with mains power and thrive in HVAC, process equipment, and general industrial duty. When fine motion, rapid reversals, or battery operation are essential, DC motors—especially BLDC—take the lead in robotics, mobile platforms, precision drives, and compact medical or laboratory devices. BLDC designs support tight speed and position control with efficient, quiet operation. Environmental conditions matter: consider ingress protection, cooling airflow, humidity, dust, and potential exposure to chemicals. For hazardous or clean zones, sealed or washdown configurations may be necessary. Where grid power is unavailable, inverters or battery packs favor DC-based solutions. If your load profile fluctuates significantly, an AC motor with a VFD or a DC motor with smart control can trim energy use while maintaining responsive, stable performance.

Cost, Maintenance, and Reliability. The best choice balances upfront price with long-term total cost of ownership. AC induction motors are often cost-effective to purchase, rugged, and simple to maintain, particularly in fixed-speed service. Adding a VFD increases initial cost but can return savings through energy efficiency, soft starts, and reduced mechanical stress. Brushed DC motors may be inexpensive and compact, yet scheduled brush replacement and commutator care add maintenance overhead. BLDC systems generally cost more at the outset due to electronic controllers but reward you with high efficiency, low wear, and extended service life. Account for downtime, spares availability, and technician skill when estimating lifecycle costs. Consider bearings, lubrication, thermal limits, and proper enclosure selection to prevent premature failures. Pay attention to power quality, harmonics, and EMI, as cleaner electrical environments improve reliability. A clear maintenance plan and realistic operating profile usually decide which technology wins over the long haul.

Choosing What Fits Your Needs. Begin with a concise checklist: available power supply and voltage, required torque-speed profile, duty cycle, precision, environmental constraints, and budget for controls and maintenance. If you need steady, continuous duty at near-constant speed with strong durability, an AC induction motor is a dependable baseline. For variable-speed process optimization and soft starting, add a VFD. If your priorities are high torque at low speeds, quick reversals, or battery operation, a DC motor is compelling; choose brushed for simple, low-cost intermittent use, or BLDC when efficiency, low noise, and longevity are paramount. When exact speed is critical, a synchronous AC motor or a BLDC with closed-loop control delivers consistent results. Plan for scaling: ensure your controller, cabling, and protections support future load changes. By mapping performance goals to these attributes, you will select a motor that aligns with your timeline, resources, and long-run success.